Ressorts Masselin has been providing parts for the railway sector since 1946.

The company’s history began with the SNCF shortly after the 2nd world war, and the experience gained from such a long collaboration means that we have a perfect working knowledge of the strict requirements in this market in terms of quality, traceability of parts and logistics.

SCOPE OF

APPLICATION

We now supply :

- All main European rolling stock manufacturers: locomotives, high-speed trains, regional trains, underground trains, trams etc.

- Operators for material maintenance

- Parts manufacturers: brakes, pantographs, doors, engines etc.

- Armoured and special vehicle manufacturers (bodies, trailers, vehicles for use in quarries etc.)

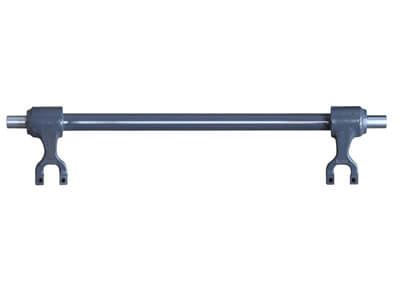

Our design office will help you develop new parts, basing its suggestions for a spring or anti-roll torsion bar on your requirements.

OUR PRODUCT FAMILIES

|

Our main two product families are as follows:

|

Other products in the range include:

|

FURTHER TECHNICAL INFORMATION

Parts undergo testing in our workshop to ensure that they meet the strictest requirements for the greatest reliability :

- Hardness testing

- Metallographic testing (metallurgical structure, decarburisation etc.)

- Lengths under load and vertical stiffness

- Lateral stiffness

- Magnetic particle inspection

- Shot peening intensity measurements

- Failure analysis with research into the cause of rupture, if required

Raw materials :

We use spring steel that is developed in accordance with the standard EN10089, mainly 51CrV4 and 52CrMoV4, and if requested, the bars are subjected to ultra-sonic testing to detect any internal defect. For smaller springs, there is the option of using stainless steels, nickel-based alloys (Inconel, Nimonic etc.), titanium (Grade 5 Ti-6Al-4V), copper beryllium (CuBe2) etc.

Protection against corrosion :

We have a powder coating facility and a liquid paint plant to ensure that our products are treated with the best possible protection against corrosion. We are approved by the SNCF and all main manufacturers.

Double-layer paint provides 1500 hours of resistance to salt spray.

GOST standards for extreme cold :

We can supply GOST-certified springs for use in very low temperatures (-60°C), as we are familiar with the Eurasian Customs Union approval process, which is particularly lengthy and difficult to pass.

Discover all of our certifications

Reconditioning :

In addition to our capacity for production, we also provide a renovation service for suspension systems and anti-roll bars, to ensure that they are fit for purpose throughout the intended service life of the rolling stock in which they are fitted, even if the parts operate in difficult conditions.